Hydroprocessed Esters and Fatty Acids, Decarboxylation

Hydroprocessed Esters and Fatty Acids

Hydroprocessing uses hydrogen to convert unsaturated compounds such as alkenes and aromatics into saturated alkanes (paraffins) and cycloalkanes, which are more stable and less reactive. The conversion is usually a two-staged process.

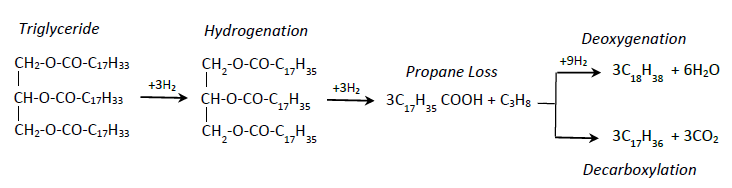

The first stage, the so-called hydrotreatment, takes place at reaction temperatures between 300 °C and 390 °C. First hydrogen is added to saturate the double bonds of the unsaturated vegetable oil triglycerides. Then more hydrogen is added to remove the propane backbone, hereby cleaving the saturated vegetable oil triglycerides to fatty acids. Finally, the fatty acids either undergo hydrooxygenation (by addition of more hydrogen the oxygen leaves as H2O) or decarboxylation (oxygen leaves as CO2 without further addition of hydrogen), or a combination of these two. The result is a mixture of straight chain, branched chain, and cyclic paraffinic hydrocarbons. (see Hydrotreatment)

from: ETIP Bioteenergy

from: ETIP Bioteenergy

Decarboxylation

This technology is focused on the second reaction, producing C02 and fuel from oil and hydrogen. This reaction consumes less hydrogen but produces CO2. It is a cheaper reaction to perform, but it is likely to be less attractive than the deoxygenation reaction following environmental concerns.

Use in Jet Fuel

Biofuels are biomass-derived fuels, from plants or waste; depending on which type of biomass is used, they could lower CO₂ emissions by 20–98% compared to conventional jet fuel. The first test flight using blended biofuel was in 2008, and in 2011 blended fuels with 50% biofuels were allowed in commercial flights. In 2019, the IATA was aiming for a 2% penetration by 2025.

Hydroprocessed Esters and Fatty Acids Synthetic Paraffinic Kerosine (HEFA-SPK) is a specific type of hydrotreated vegetable oil fuel used in aviation.As of 2020 this is the only mature technology.HEFA-SPK fuel is considered as leading alternative replacements for conventional jet fuel by the CAA because of its sustainability. HEFA-SPK was approved by Altair Engineering for use in 2011. HEFA-SPK is produced by the deoxygenation and hydroprocessing of the feedstock fatty acids of algae, jatropha, and camelina. (see Aviation Fuel)

Sources

Physical Data regarding HVO Fuel are from F3 and ETIP Bioenergy

Technico-economic information (Capex, Opex, Production levels, past investments, ...) are coming from:

- Tao, L., Milbrandt, A., Zhang, Y. et al. Techno-economic and resource analysis of hydroprocessed renewable jet fuel. Biotechnol Biofuels 10, 261 (2017).

- Noah, Matthew. A Techno-Economic and Environmental Assessment of Hydroprocessed Renewable Distillate Fuels. (2011)

- Diederichs, G.W. Techno-Economic Assessment of Processes that Produce Jet Fuel from Plant-Derived Sources. (2015)

- IEA Bioenergy. Progress in Commercialization of Biojet /Sustainable Aviation Fuels (SAF) (2021), License: CC BY 4.0.

- ETIP Bioenergy. HVO/HEFA

- De Jong, S., Antonissen, K., Hoefnagels, R. et al. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol Biofuels 10, 64 (2017).